Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

Tumble belt shot blasting machine can handle work piece at weight from 1KG to 500KG with different models and the maximum weight can be even higher. It works perfectly in all fields of surface cleaning, rust removal, oxidation layer removal and surface strengthening for small forgings, castings, stamping parts, gears, springs etc., especially for work pieces that are suitable for tumbling with each other.

Tumble belt shot blasting machine is a design of roller style with rubber belt or steel belt. Ultimately compact with smart design and small floor space occupation. Economic style solution with powerful capacity of cleaning thoroughly every side of work pieces that aresuitable for tumbling. It is an ideal option for blasting and cleaning work pieces in batches to have optimum blasting results on small delicate metallic parts, heavy castings, partially covered with sand or scale. Work pieces are loaded into the blasting chamber manually or automatically with loading & unloading system. In the process of blasting, work pieces are continuously cascading and tumbling over each other, resulting in all-around blasting coverage with high efficiency. Work pieces touch and contact each other during the tumbling make it even easier for blasting process.

Automatic loading and unloading system makes Mayflay tumble belt shot blasting machine a typical & optimized choice to have reliable quality, extremely long lifespan, high efficiency of blasting and save cost of labor.

Applicable Work pieces

Transport system: Rubber belt

Surface condition before shot blasting: Rust, Scalings

Advised load weight per batch: 500kgs

Max. Single workpiece weight: 100kgs

Number of Blast Wheels: 1 set

Suitable Work pieces:Small casting parts, forging parts, stamping parts, spring,

Gears, bolt and so on.

Hydraulic loading and unloading system is optional

More options of configuration

Option for customization of high-quality perforated rubber belt or hardened steel belt. Design with diversity for perfectly handling different kinds of work pieces, such as sand cleaning of forgings, oxidation layer cleaning and surface cleaning of work pieces with heat treatment.

Option to have automatic loading and unloading system that provides constant, stable blasting results with high performance to increase overall productivity, reduce unproductive times.

Option to get magnetic separator for work pieces like sand castings.

High efficiency of shot blasting & flexibility of integration

Work pieces roll and tumble together in the roller belt to have every side and part of surfaces thoroughly blasted with our specially-designed blasting wheel. This tumble belt blasting machine can be easily integrated into complete manufacturing lines with fully automatic operation.

Excellent quality building

Blasting machine body: 6mm thickness Manganese 13 steel plates welled welded in one

piece and Manganese 13 steel protective boards, offering excellent wear resistance and protection from even the most aggressive blast media. This guarantees a long equipment life with a high uptime and low maintenance cost.

Easy control, easy operation, easy maintenance

PLC control, all process parameters of work pieces blasting can be configured and saved in PLC control unit, in the result that repeat input, repeat pushing different buttons are completely unnecessary. This means, much shorter time of parameter configuration, much less working hours of operator and high efficiency. Maintenance and examination windows are set on each core working parts of this machine for easy maintenance.

Environment friendly

Mayflay has been focusing on protection of environment, noise and dust emission are the most important aspects we care about. We adopt high-end methods to reduce noise to 85DB and dust emission concentration to less than 50mg/m3 (these results can be even better with higher standard of configurations).

Blasting chamber system

a.4-10mm thickness Manganese 13 steel plates well welded in one piece.

b.A line of Mn13 steel protective boards, hung on the exposed area to the blasting shots to provide perfect protection to the blasting chamber body.

c.Excellent sealing design to prevent shots spillage during blasting. Absolutely no shots spillage out of the blasting chamber.

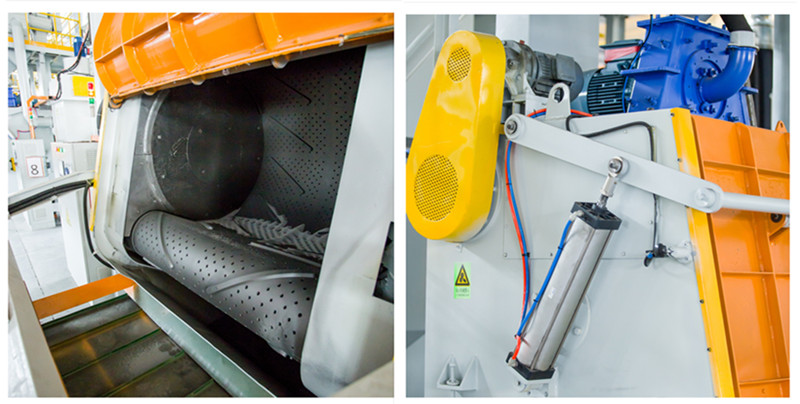

Automatic open and shut double door, supported and driven by 2pcs hydraulic cylinders.

Automatic loading & unloading system

a.The hydraulic system is an independent and integrated driving device, consisting of motor, bump, solenoid directional valve, oil control valve, throttle valve, and oil tank and so on.

b.Put work pieces into the loading bucket and press the start button, the loading system will transport all work pieces into the blast chamber.

c.When the blasting work is finished, the doors of the blasting chamber open and the tumble belt rotates from this other way around, so all work pieces are unloaded from the chamber onto the rubber conveyor and transported for collecting.

Only a press of the button, blasting work automatically done.

Tumble belt system

a.Driving motor is installed on the chamber to drive the driving axle, front axle, rear axle and rubber belt to tumble the work pieces on the belt.

b.Variable-frequency speed adjustment system is installed for the belt and speed can be adjusted and control according to requirements.

work pieces are continuously cascading and tumbling over each other, resulting in all-around blasting coverage with high efficiency, making it even easier for blasting process.

Screw conveyor system

a.One screw conveyor is positioned at the bottom of the blasting chamber. It includes screw axle, blades and screw heads at both sides. Blades are soldered on the screw axle. It is driven by the gear motor of the bucket elevator.

b.During working, the screw conveyor transits the shots to the bottom of the bucket elevator and the shots are lifted by the buckets to the upper part of the elevator and put into the shot separator.

Another screw conveyor system is installed at the top side of the bucket elevator to both push shots to the shots separator and separating partial dust and small broken shots through the roller filter.

Bucket elevator system

a.It includes, 2pcs high-quality wheel hubs, 1 elevator body, 1 high-performance and durable belt and several alloy buckets.

b.It collects and lifts the shots recycled by the screw conveyor onto the separator and storage cabinet.

Driven by 1 gear motor at the top of the elevator and built with steel plates by accurate soldering technique and can be disassembled into several pieces.

Separator system

a.Air-flow separator is used to separate good shots and broken shots and dust. It is built and soldered with steel plates and different chambers are designed inside to lead the air flow.

b.Mixture of shots & dust is transported from the screw conveyor (if equipped) and goes downward on a sliding steel board and get into the way of the air flow. Good shots are heavy and not driven to move by the air flow but broken shots are much lighter to be lead to the other slide board to be connected with collector/bucket. Dust directly sucked and taken to the air outlet to the dust collector.

c.Multi-level steel plates are installed to adjust and balance the sliding shots flow amount. Good shots are collected by the shots storage cabinet for recycling usage.

Semi-automatic flow valve

a.Semi-automatic flow valves, fully sealed with lockable examination window, are equipped to control the flow amount of shots into the blast wheels.

On the top of each flow valve, in case steel shots flow from the storage silo, a manual stop valve can be switched off under the circumstance of examination, repairing and maintenance.

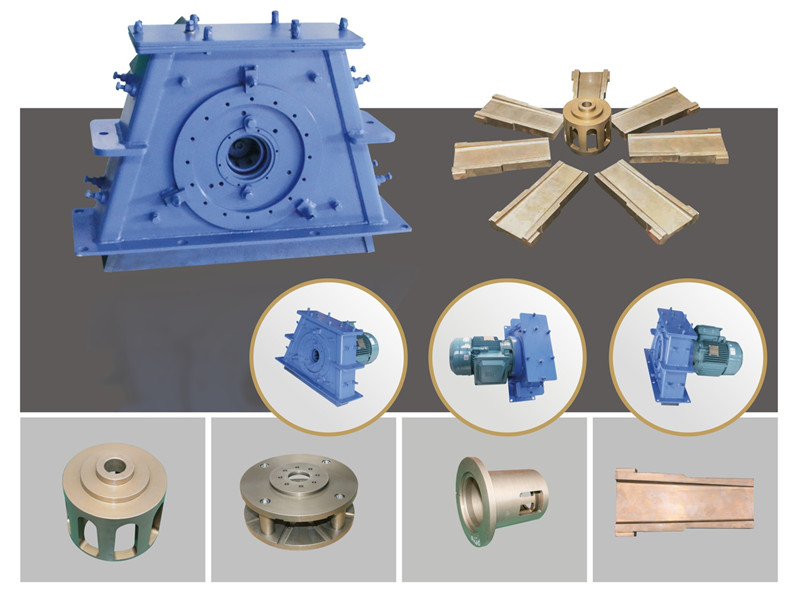

Blast wheel system

a.Thanks to German technology, Mayflay casting and fully CNC machined blast wheels are designed and manufactured with highly hard-wearing materials and steel plates for easy replacement and maintenance.

b.Designed and manufactured in combination of our own industrial advantages and features to have excellent performance of dynamic balance and perfect shots output efficiency.

c.Highly hard-wearing materials and steel plates are installed inside for easy replacement and maintenance, working with variable-frequency speed control technology to control and adjust the power of the blasting.

d.Mayflay P series power system (available), specially-designed and manufactured ABB motor, die steel CNC machined + low-pressure & vacuum heat treatment vulnerable parts inside. These special vulnerable parts have 58-62HRC surface hardness that is extremely durable and has super long lifespan.

Dedusting System: cartridge filter with secondary filter system

a.Typical dedusting system for shot blasting machine, including a secondary filter system cyclone separator and a cartridge filter. Most of heavy dust is separated and collected in the cyclone separator and the escaped air & dust mixture goes into the cartridge filter in which the dust is blocked and filtered by the filter inside and fresh and clean air goes through the filter to go out.

b.Electromagnetic pulse technology is used to separate the dust and the filter and dust goes down to the collect storage cabinet due to its gravity.

c.The built-in filter needs regular cleaning and replacement to prevent the spillage of dust from inside because of the blocked and malfunctioned filter.

d.This dedusting system works with silencer and secondary filter to ensure that noise emission is lower than 85DB and dust emission is lower than 50mg/m³

e.Wet dust collector is available. High performance dedusting system, with Venturi theory, is a great dust separator especially for flammable and explosive media. Wet dust is automatically recycled and the electromagnetic water valve automatically open to provide new water when the water level in the water box is low.

Electric Control Cabinet

a.PLC : Siemens

b.Frequency converter: Brand optional

c.Low voltage electrical components: Brand optional

10 inches color touch screen

Machine Model | MB-100Q7.5-1 | MB-100P7.5-1 | MB-200Q11-1 | MB-200P11-1 |

Max. loading volume (L) | 100 | 100 | 300 | 300 |

Max. recommended charging weight (kg) | 150 | 150 | 300 | 300 |

Max. recommended piece weight (kg) | 5 | 5 | 10 | 10 |

Width of shotblasting chamber (mm) | 650 | 650 | 1100 | 1100 |

Diameter of shotblasting chamber (mm) | 650 | 650 | 100 | 100 |

Blast wheels Model | Casting | CNC processing | Casting | CNC processing |

Diameter of blast wheel (mm) | 280 | 280 | 380 | 380 |

Power of abrasive blast wheels (kW) | 7.5 | 7.5 | 11 | 11 |

Air requirements (m3/h) | 3600 | 3600 | 5000 | 5000 |

Hydraulic Loading System | Optional | Optional | Optional | Optional |

Discharging System | Optional | Optional | Optional | Optional |

Can be customized accoridng to customer's requirements | ||||