Hotline

+86-13692841862

Email:info@mayflay.com

Add::NO.289,Guangreng Rd,Xiaojinkou Str.Huicheng Dis,Huizhou City,Guangdong Province,China.

Surface Treatment Equipment

Coil Handling Equipment

Solutions

Application

About us

welcome to MAYFLAY

For consultation/feedback, please call the service hotline: +86-13692841862 Email:info@mayflay.com

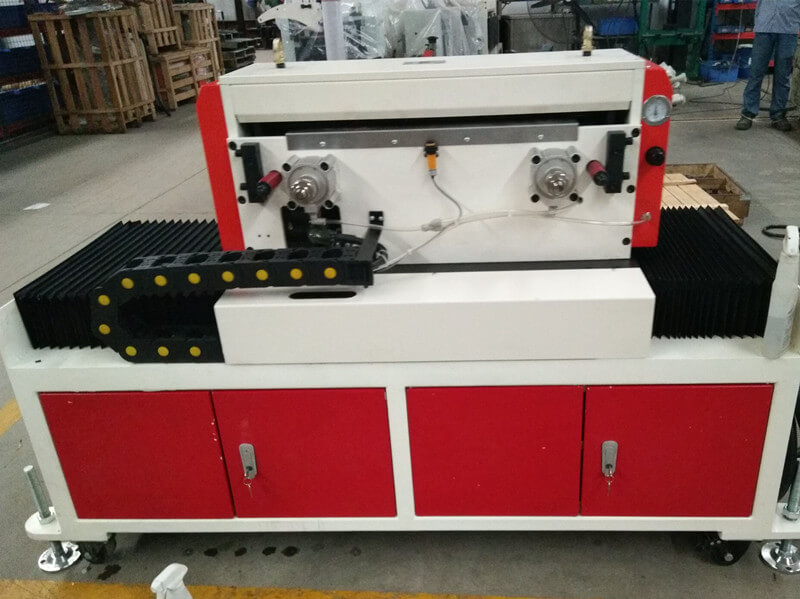

Zigzag NC servo Feeder is designed to for circle blanking line, with high efficient processing and save material utilization function.It can be suitable for all kinds of circle, round cover and washer stamping.

Zigzag NC servo feeder production line is suitable for motor blanking, motor compressor shell, aluminum wafer, kitchen appliances, lighting products, auto parts, stainless steel products and other industries.

Zig-Zag Servo Feeder offer dramatic productivity advantages in stagger feeding. Stagger feeding parts in a Zig-Zag Press Feed System can boost productivity and provide up to 22 % material savings. Zig-Zag Servo Feed controls are operator friendly and automatically calculate and set up all machine parameters quickly and accurately. Servomax Zig-Zag Servo Feeds provide fast, easy set-up in a single or dual axis format. The control automatically calculates the optimum movement in each axis and the feed can simultaneously or sequentially deliver the material in X-Y movement. 2 or 3 out pattern capability is standard with up to 6 out pattern optional.

Zigzag Servo feeder machine is driven by an AC Servomotor through a precision gear train while the lateral travel of the feed and material is powered by a combination AC Servomotor and linear ball screw. The ServoMatic and ServoMax Servo Press Feeds can be press mounted or Cabinet mounted. The SMX H and H6 Servo Roll Feeds are cabinet mounted.

This zigzag Nc Servo feeder production line with high Efficiency, saving material utilization rate of washer drawing function, can be a variety of coil material by uncoiling, straightening, punching, shift around circular plate is the efficient processing of different specifications of pipeline materials under the sheet metal processing wafer. We also cam add the auto stack device, can be collected the circle into wafer stacking.

This zigzag NC servo feeder production line is suitable for lamps, ceiling lamps, eletric cooker, pot, tea class punching, stainless steel tableware, water pump, water heater , bearing retainer, fire extinguisher, filter and accumulator, motor stator, rotor, motor shell electronic, the refrigerator compressor, air conditioner compressor casing , auto clutch, car pulley, automobile wheel Hub, brake disc stamping.

Model | NCP-200 | NCP-300 | NCP-400 | NCP-500 | NCP-600 | NCP-800 |

Coil Width | 200 mm | 300 mm | 400 mm | 500 mm | 600 mm | 800 mm |

Strip Thickness | 0.2-2.0 mm | |||||

Release | Pneumatic Type Releasing System | |||||

Roll Pressure | Spring Type | |||||

Feed Roll | Upper Roll 1pc, Bottom Roll 1pc | |||||

Feed Length | Max. 9999.99 mm | |||||

Speed | Feeding Speed Max. 20 m/min, Zigzag Movement Speed Max. 30 m/min | |||||

Left Center Displacement | 100 mm | 150 mm | 200 mm | 250 mm | 300 mm | 400 mm |

Accuracy | ± 0.1 mm | |||||

Servo Motor | Yaskawa, Japan | |||||

Servo Drive | Yaskawa, Japan | |||||

PLC | Mitsubishi, Japan | |||||